- New products

- Sold Out

- Abrasives

-

Clamps

- Malleable cast iron screw clamp TG with 2-component plastic handle

- Heavy duty malleable cast iron sctrew clamp TGK with 2-component plastic handle

- Malleable cast iron screw clamp TG with tried-and-true wooden handle

- Heavy duty malleable cast iron screw clamp TGK with tried-and-true wooden handle

- Malleable cast iron screw clamp TG with tommy bar

- Heavy duty malleable cast iron screw clamp TGK with tommy bar

- Malleable cast iron screw clamp TPN with 2-component plastic handle

- Malleable cast iron screw clamp TPN with tried-and-true wooden handle

- Heavy duty malleable cast iron screw clamp TKPN with tried-and-true wooden handle

- Heavy duty malleable cast iron screw clamp TGKR with tried-and-true wooden handle

- Malleable cast iron deep throat screw clamp TGNT with tried-and-true wooden handle

- Malleable cast iron deep throat screw clamp TGNT

- All-steel screw clamps GZ with 2-component plastic handle

- All-steel screw clamps GZ with swivel handle

- All-steel screw clamps GZ with tried-and-tested wooden handle

- All-steel screw clamps GZ with tommy bar

- All-steel screw clamps classiX GS with tried-and-tested wooden handle

- All-steel screw clamps classiX GS with tommy bar

- OMEGA all-steel screw clamp GMZ with 2-component plastic handle

- OMEGA all-steel screw clamp GMZ with tommy bar

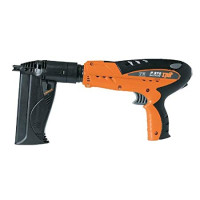

- Nailers and staplers

- Kreg tools

- Halder soft-face mallet

- Picard hammer

-

Power tools

- Festool 18 V promotion

- Cordless circular saw

- Cordless jigsaws

- Cordless sanders

- Cordless drills-screwdrivers

- Cordless dust extractors

- Cordless hammer drills

- Cordless angle grinder

- Cordless nailers and staplers

- Cordless Oscillating / Multi-Tools

- Cordless reciprocating saws

- Cordless blowers

- Cordless caulking gun

- Cordless insulating-material saws

- Working light / speakers

- Cordless speakers and radio

- Battery packs and chargers

- Accessories

- Balancers and retractors

- Concrete and steel fixing

- Fixing systems

- Wood repairing

- Cleaning products

-

Cutting tools

-

Hand tools

- DeWALT tools and accessories

- Washing and cleaning equipment

- Coating materials

- Varnishing, painting equipment and tools

- Personal protection equipment

- Measuring tools

-

For Garden and Home

- Ladders, ladder accessories

- Scaffolding and staging

- Fan shop

Description

Supercraft 3366.030 soft-face mallet with hickory handle

The tubular head of the Halder Supercraft 3366 mallets is filled with steel shot. The resulting effect is that the energy of the steel shot is transferred with a slight delay when the mallet's contact surface hits the workpiece. The reduced rebound allows the impact energy to be absorbed with perfect efficiency. The result is an impact of exceptional magnitude. Halder Supercraft mallets allow for work with greatly improved safety, reduced strain on the joints and greater noise-dampening when compared to ordinary steel mallets.

The ergonomically shaped, varnished and ultra-stable hickory handle has a vibration-dampening effect.

The inserts offer outstanding impact qualities and are guaranteed to combine maximum strength with unique durability. They consist of extruded and extremely homogeneous material. Compared to injection moulded plastic inserts, they are therefore considerably more wear-resistant and durable and will never chip even in sub-zero temperatures.

The handle protection sleeve acts as an overstrike protector. A secure handle-head connection is ensured by an aluminium wedge and a safety pin. All weld seams are completely robot-welded. Extremely tight and of premium quality, a welded connection between the impact plate and hammer head keeps the steel shot filling from escaping even under maximum load. The wear-resistant powder coating prevents corrosion.

Handles and inserts are replaceable.

This Halder Supercraft 3366 series is available in sizes ranging from D20mm to D80mm and as a sledge hammer weighing up to 9,300g.

Technical data

- Insert working surface diameter - 30 mm

- Hammer head height - 110 mm

- Total hammer length - 330 mm

- Weight - 0,460 kg

- Handle - hickory wood

- Inserts - Nylon, white, hard, very wear-resistant, no chipping (even at temperatures below zero), noise-dampening, very high impact

Application

Positioning and joining of workpieces in the vice sheet-metal forming, assembly of sharp-edged workpieces, assembly and repair work in the automotive and truck sector, scaffold construction, straightening work, housing assembly, plant construction, maintenance work, driving in cord irons/metal stakes, for work with great power, prying work, upholsterer/saddler, hole punching with hole punches, driving eyelets with eyelet punches, driving in cramps

Supercraft soft-face mallet with vibration-reducing Nylon, D25mm, 305mm

38.59€

In Stock: 2

Product Code: 3366.225

Supercraft soft-face mallet with vibration-reducing Nylon, D30mm, 330mm

40.66€

In Stock: 2

Product Code: 3366.230

Supercraft soft-face mallet with vibration-reducing Nylon, D60mm, 360mm

88.29€

In Stock: 1

Product Code: 3366.060

Supercraft soft-face mallet with vibration-reducing Nylon, D30mm, 330mm

34.03€

In Stock: 2

Product Code: 3366.030

Supercraft soft-face mallet with vibration-reducing Nylon, D40mm, 355mm

42.21€

In Stock: 2

Product Code: 3366.040

Supercraft soft-face mallet with vibration-reducing Nylon, D50mm, 365mm

51.38€

In Stock: 2

Product Code: 3366.050

Supercraft soft-face mallet with vibration-reducing Nylon, D60mm, 325mm

80.38€

In Stock: 2

Product Code: 3377.160

Supercraft soft-face mallet with vibration-reducing Nylon, D40mm, 305mm

43.14€

In Stock: 2

Product Code: 3377.140

Supercraft soft-face mallet with vibration-reducing Nylon, D50mm, 315mm

51.80€

In Stock: 2

Product Code: 3377.150

Picard full steel carpenters' roofing hammer nr.620M, 760gr.

38.05€

In Stock: 3

Product Code: 0062010

*The images of the Products displayed on the Website are for illustrative and informative purposes only. The picture of the goods may differ from the actual packing size and appearance of the goods and the images may show parts that are not included in the delivery of the goods

Pamanījāt kļūdu? Ziņojiet mums

Pamanījāt kļūdu? Ziņojiet mums